This Boyar Schultz surface grinder was purchased for a song. I agreed to restore it. Here is a reverse chronological build log. Here is a play list of the restoration process:

6/2017

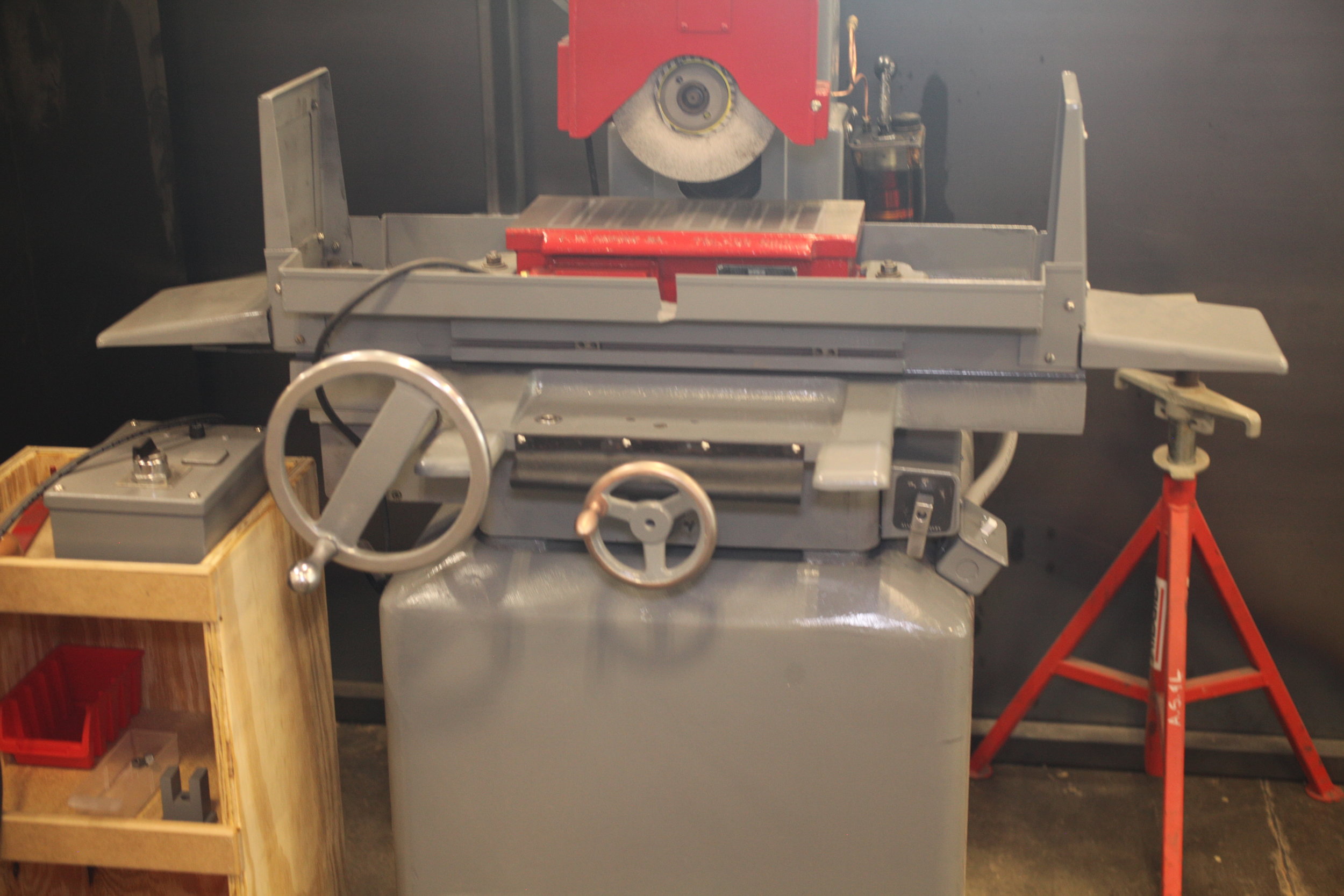

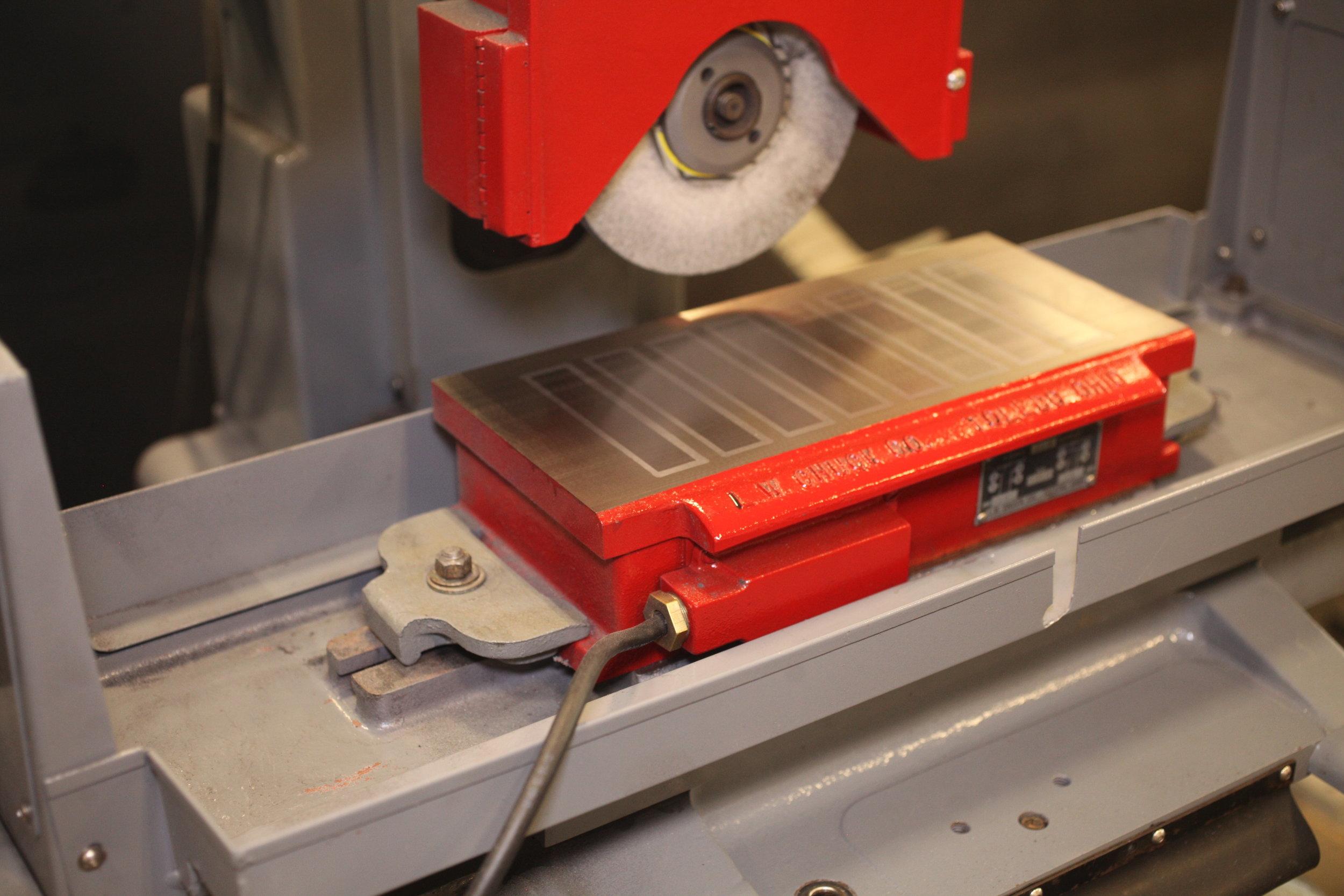

Surface grinder is re-assembled and put into operation:

3/2017

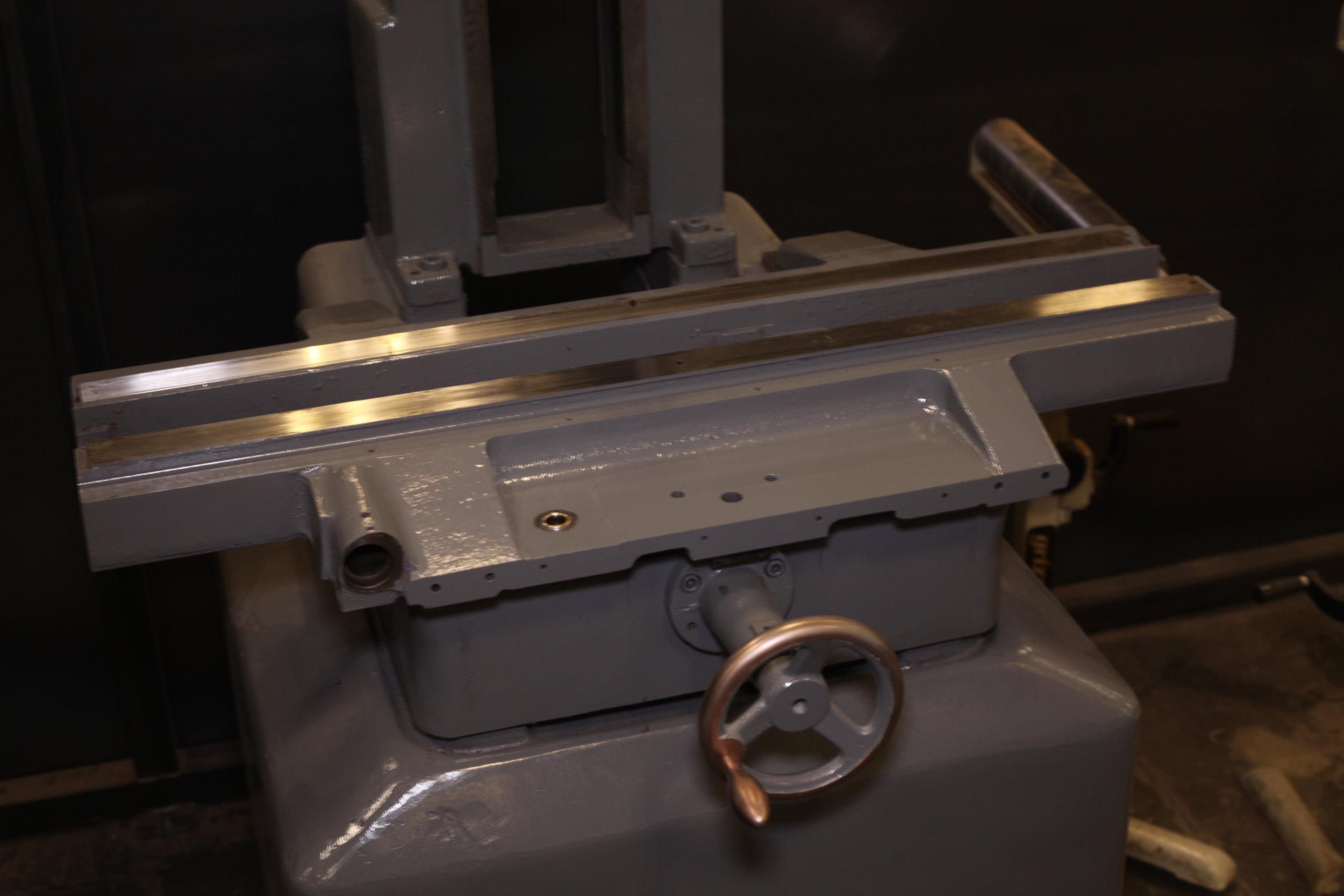

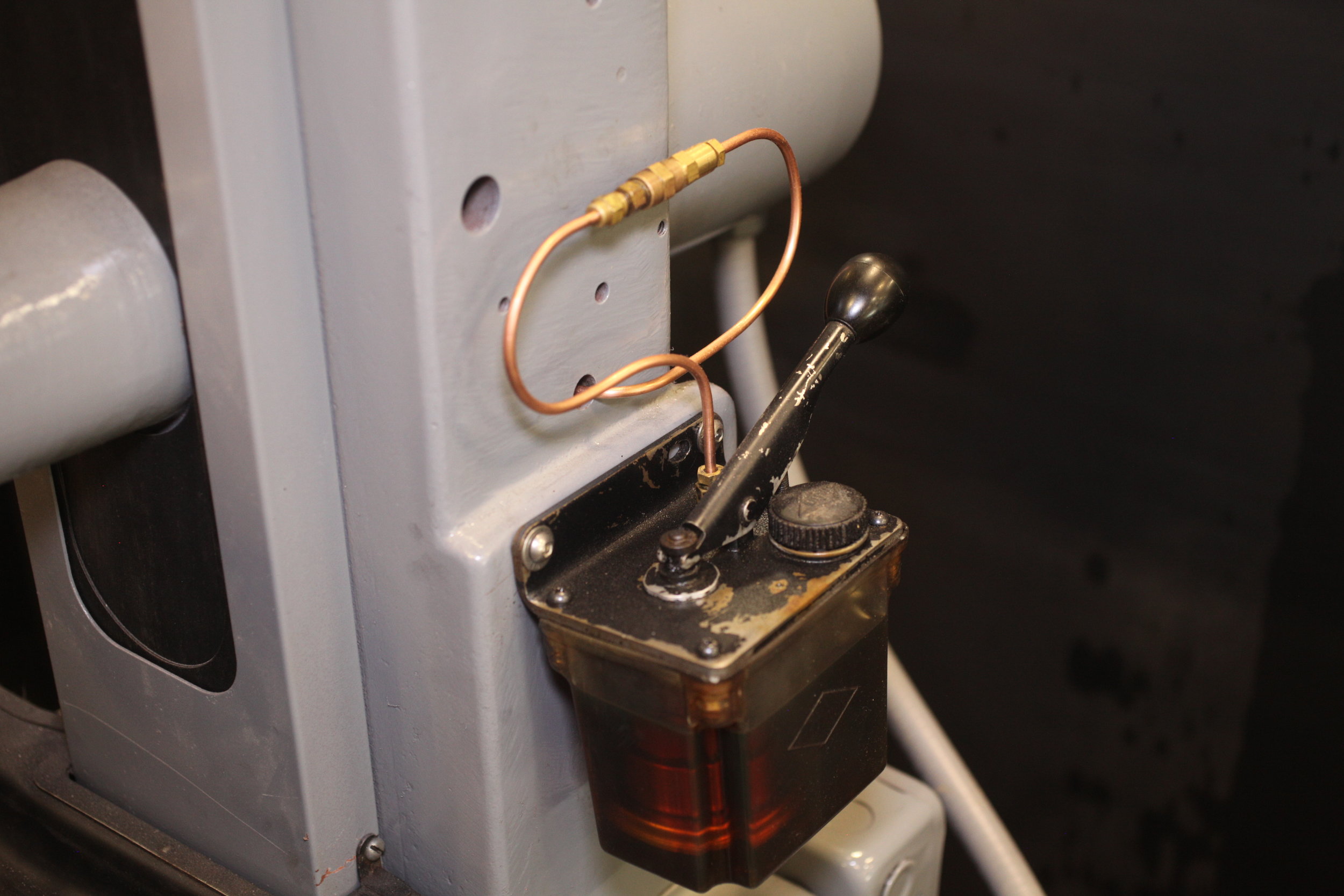

All of the parts had their masking removed and reassembly began. Here are the bed and cross slide looking brand new:

I leveled the base side-to-side and front-to-back by placing a straight edge on two spacers on the grinder mounts. A machinists level ensured the base was quite level.

The leveling bolts were de-rusted, sand blasted, then heated to 470 degrees for an hour. This caused them to uniformly oxidize to a purple/copper color. Then they were rubbed with oil for protection. Here they have been installed back into the painted grinder after some anti-seize has been applied.

Hand wheels were polished on the edges, then masked and given the same priming and painting. Here are the finished wheels.

All parts received a good coat of Rustoleum Professional Smoke Grey Enamel, thinned per the instructions on the container.

1/2017

All parts were primed with Rustoleum "Rusty Metal" primer.

New guard plates were made on the water jet.

11/2016

The original motor plate.

The "before" picture.

Picking up the old grinder.